Business Introduction

Main lines of products boasted by ASAI SANGYO with experience of 95 years since its foundation

Steel

Since its foundation, the core business of ASAI SANGYO is: "Steel"

Since its founding, the core business of ASAI SANGYO is steel.

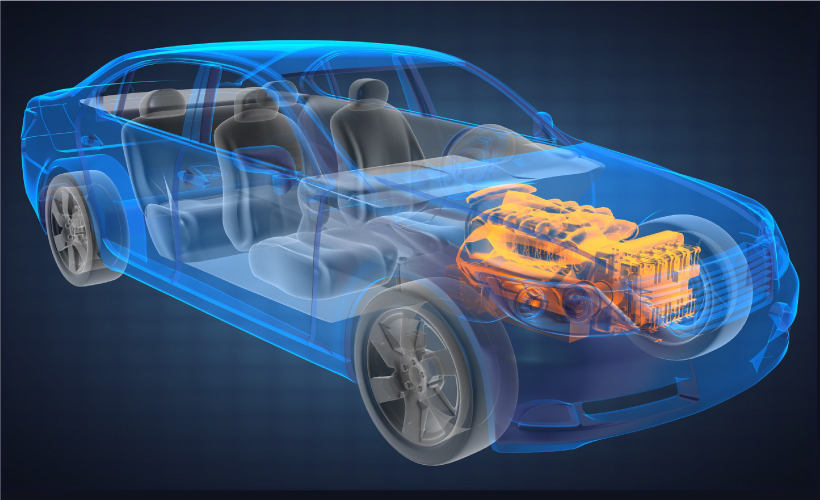

A car is made from about 30,000 parts. Our handling materials include thousands of parts, which are useful in invisible places such as engine parts of each automobile, motorcycle and construction machine.

The steel materials (special steel) handled by our company are used for familiar products.

Familiar products for which steel materials are used

Automobile

Automobile

Bus

Bus

Heavy equipment

Heavy equipment

Parts inside a car

Crankshaft and connecting rod

Crankshaft and connecting rod

Bolt and nut

Bolt and nut

Gear

Gear

Lower arm and ball joint

Lower arm and ball joint

Special steels handled by our company

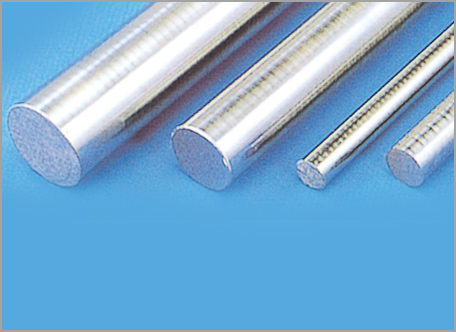

Special steel (bar steel)

Special steel (bar steel)

Special steel (wire rod)

Special steel (wire rod)

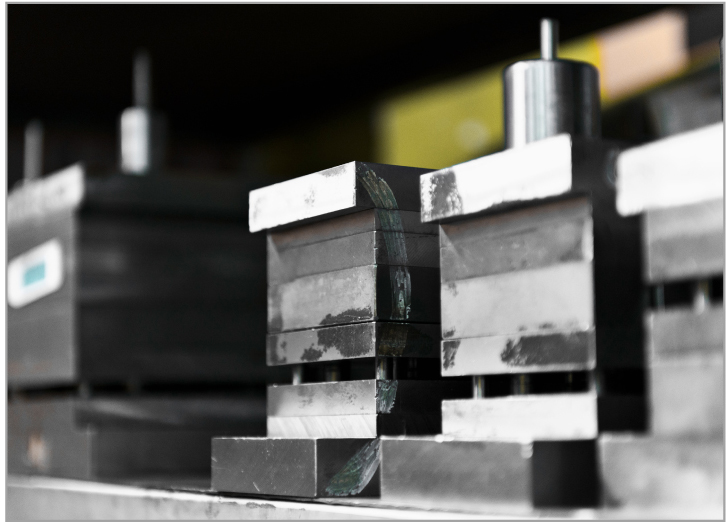

Special products (materials of such as tools and dies)

Die material "special product" for forming automobile parts

Special steels that are extremely hard and can withstand the heat of 1000℃ or higher are also used as dies for various industrial products such as a die for baking Taiyaki (fish-shaped cake). There are very different kinds of steels, such as tool steel, high speed steel and powdered high-speed steel.

The tools and dies handled by our company are used as a part of tools for forming all kinds of products.

Tools and dies are extremely important as a part of tools for making all kinds of products.

Since the materials for making the tools and dies also have a great influence on the function, we need sufficient knowledge and expertise in their selection.

Examples of products

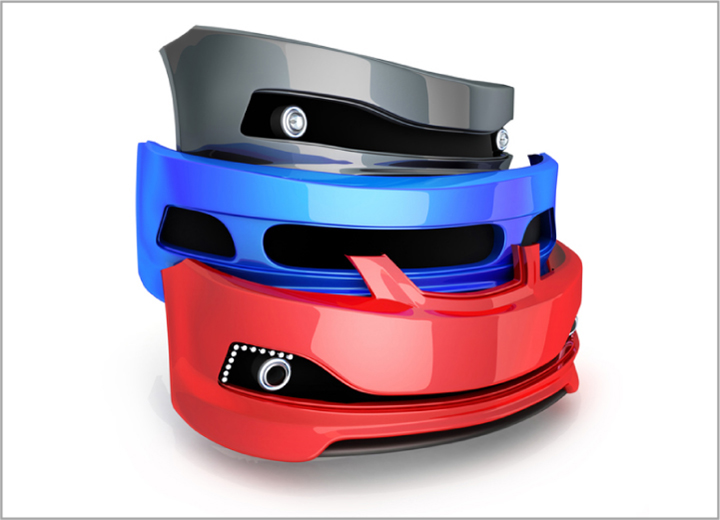

Bumper

Bumper

Engine

Engine

Parts

Engine parts

Engine parts

Die for making products

Die for making bumpers

Die for making bumpers

Tool for machining parts

Tool for machining engine parts

Tool for machining engine parts

Materials for making dies handled by our COMPANY

(Plastic die steel)

Materials for making tools handled by our COMPANY

(Special steel specialized manufacturer)

Photo courtesy: Nippon Koshuha Steel Industry

Aluminum and Copper

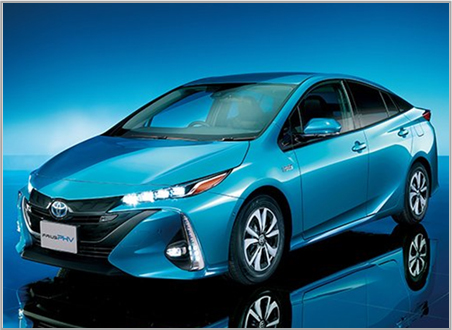

"Aluminum and copper" for future cars

Features of aluminum: It is lighter than iron (1/3 weight), easy to process, easy to recycle, a 21st century type recycling material indispensable to the present day.

It is used in 10% of car components. (160 kg/unit)

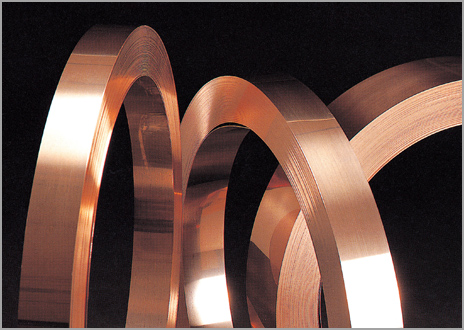

Features of copper: It is a metal used by mankind for the first time.

It is used for precision electronic parts such as hybrid cars and smartphones, and is an indispensable material of our lives.

Aluminum and copper materials handled by our company are used in your familiar products.

Familiar products for which aluminum and copper materials are used

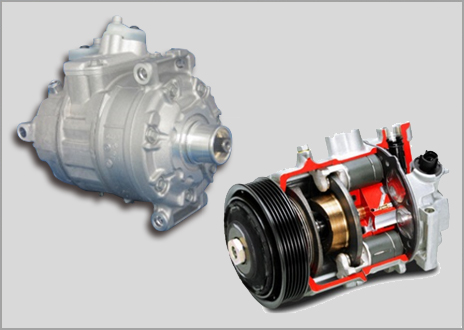

Automobile (Air conditioning related parts)

Automobile (Air conditioning related parts)

Automobile (Engine related parts)

Automobile (Engine related parts)

Personal computer and smartphone

Personal computer and smartphone

Parts, products, etc.

Car air conditioner parts, and others

Car air conditioner parts, and others

Heat insulator

Heat insulator

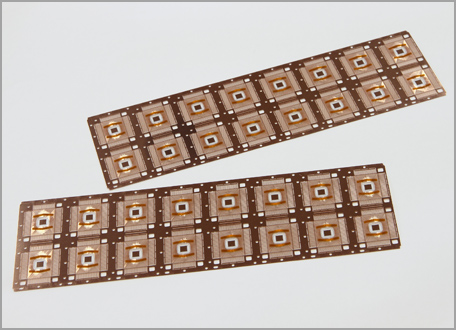

Lead frame for semiconductors

Lead frame for semiconductors

Aluminum and copper materials handled by our company

Aluminum extruded material

Aluminum extruded material

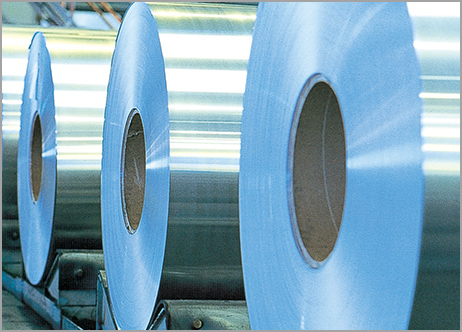

Aluminum plate

Aluminum plate

Copper plate

Copper plate

Coating

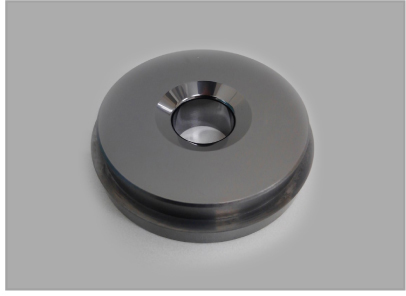

"Coating" for increasing the life of die

Coating technology for increasing the life of die. Coating is required for tools and dies which are indispensable in making automobile parts.

The role of tool and die is to grind a part, to drill a hole, and to strike the material. We are helping the surface membrane technology for dramatically improving smoothness and durability. How to thinly and effectively deposit the film -- that is exactly a micro battle!

Being specialized in automobile parts, our company became the top manufacturer in this field.

The coating handled by our company is useful for extending the life and improving the function of dies and tools to form all kinds of products.

Tools and dies are extremely important as a part of tools to make all kinds of products.

Since the materials for making the tools and dies also have a great influence on the function, we need sufficient knowledge and expertise in their selection.

Coating (surface treatment) process

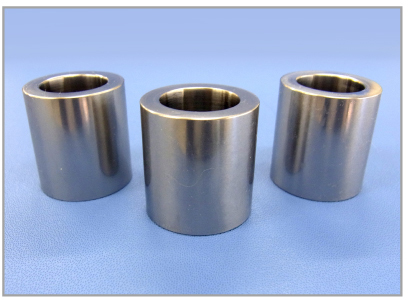

Various jig tools for pre-coating treatment

Various jig tools for pre-coating treatment

Coating device

Coating device

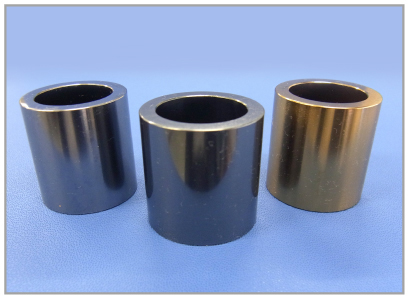

Various jig tools for post-coating treatment

Various jig tools for post-coating treatment

Cutting tool (chip) for processing iron in pre-coating treatment

Cutting tool (chip) for processing iron in pre-coating treatment

Coating device

Coating device

Cutting tool (chip) for processing iron in post-coating treatment

Cutting tool (chip) for processing iron in post-coating treatment

Various cutting tools for pre-coating treatment

Various cutting tools for pre-coating treatment

Coating device

Coating device

Various cutting tools for post-coating treatment

Various cutting tools for post-coating treatment

Mold

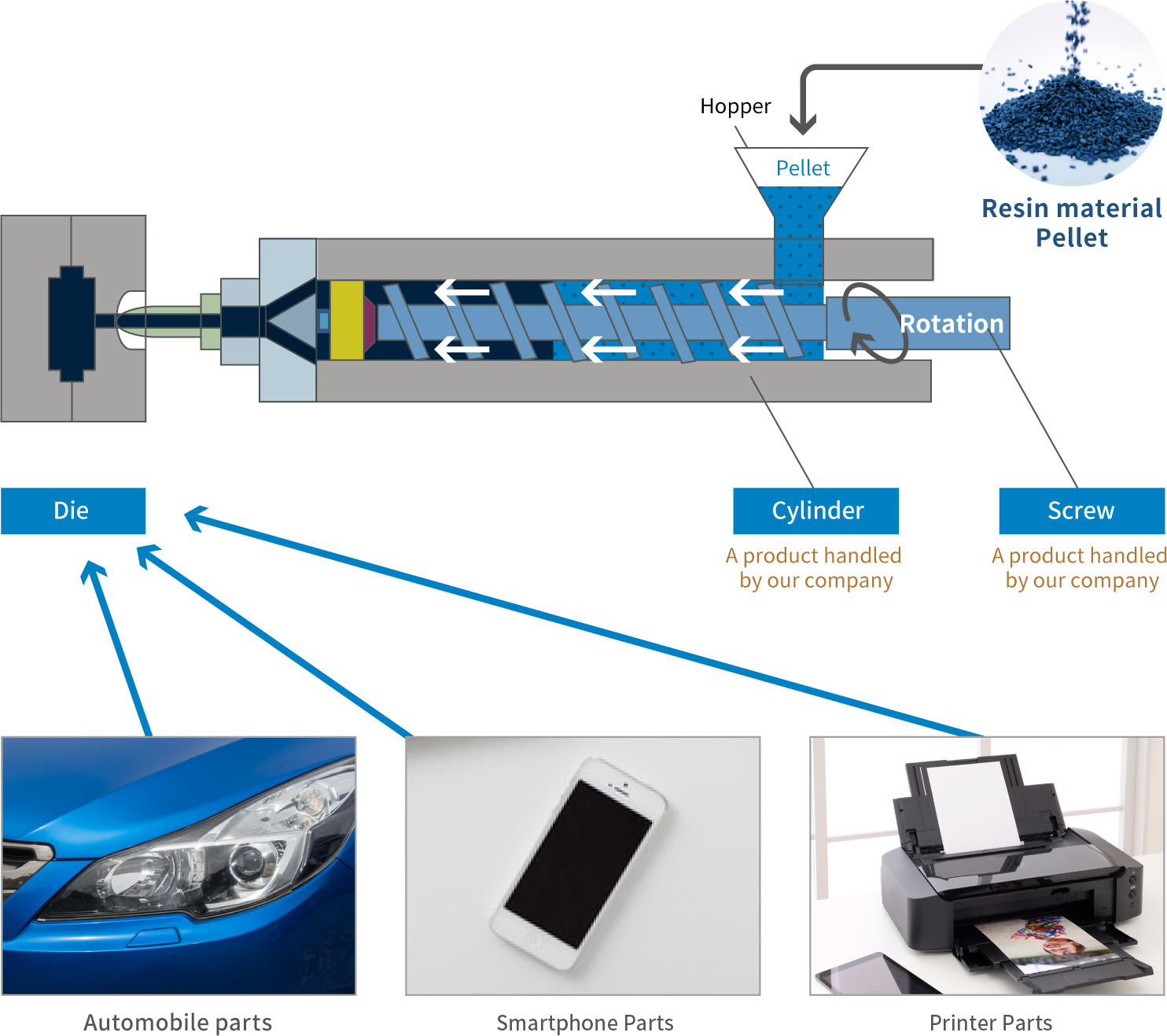

"Mold" for familiar plastic products

In order to make plastics, materials, dies and injection molding machine are necessary. ASAI SANGYO involves in the parts related to injection molding machines.

To make plastic products, materials are melted with an injection molding machine to pour them into a die. Plastics are also used for smartphones and personal computers, which are indispensable to our daily lives.

We sell the main parts of a machine for manufacturing highly functional resin (engineering plastic) products.

We sell the main parts of a machine called the Injection Molding Machine for manufacturing products made of highly functional resin (engineering plastic).

We have earned high praise from machinery manufacturers and parts manufacturers by being evaluated with high knowledge and uniqueness.

Illustration of an injection molding machine

Machinery and environmental equipment

Offering solutions to global environmental issues

Small efforts add up to protect the global environment and ourselves.

(1) Energy efficiency

(2) Decarbonization and next-generation energy

(3) BCP measures

(4) Workplace improvement

(5) Longevity, preservation, and waste reduction

(6) Storage and management

*We offer and sell a variety of products.

We specialize in energy efficiency, decarbonization, next-generation energy, BCP measures, and other environmental machinery and equipment, adopted and highly rated by major automobile and parts manufacturers based on our high level of expertise.

Please refer to the details page and digital catalog for our main products

Expanding our business to Asian regions

We are expanding our overseas business in a wide range of sectors.

[Iron & Steel]

We import and export special steel wire rods, steel bars, secondary processed products, forging and cutting parts, tool steel, molds, and more.

[Non-Ferrous Metals]

We export aluminum extrusions, sheets, copper sheets, aluminum castings and forgings, and cutting parts.

[Molding]

We export and import parts related to injection molding machines.

[Overseas Subsidiaries]

At ATC (Thailand) and AI/ASP (Indonesia), local employees work together with our domestic sales department to conduct sales activities.

Logistics (Kinuura Service Center)

As a steelmaker's warehouse, we will store materials carefully.

[Warehouse function]

As a steelmaker's warehouse, we store materials carefully.

[Delivery function]

We deliver our products according to customers' request "with only the necessary amount of necessary products when needed."

[Inspection function]

Under the guidance of the manufacturer, we are inspecting the products, to verify "whether there are any scratches on the materials" and "whether they are bent", etc.